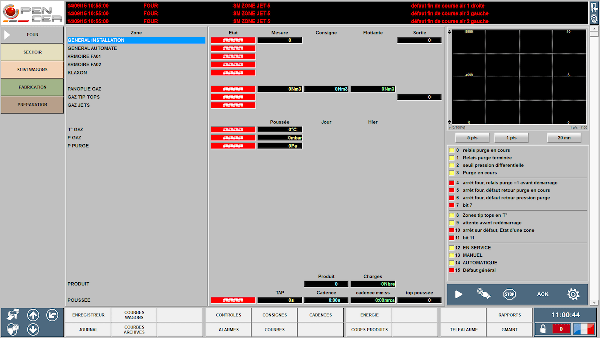

Process follow-up

In order to control the good running of regulation processes, we propose graphical interfaces, such as animated graphics, indicators, instantaneous and contextualized firing/ drying curves:

We are continuously adapting to our clients’ industrial process to provide customized solutions for each production site.

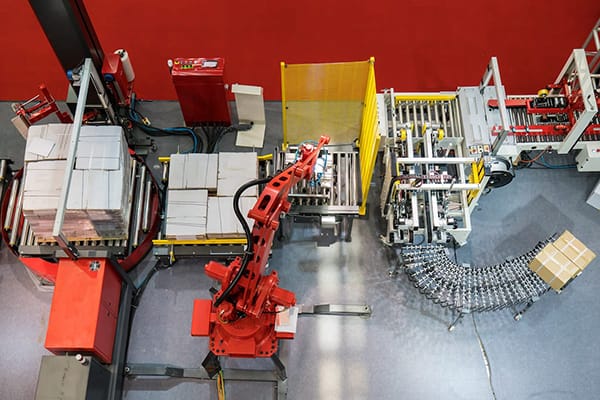

Products tracking

Products are tracked and identified at each step of the manufacturing process, allowing so data traceability and automatic management of regulation recipes and/or of machine data (settings).

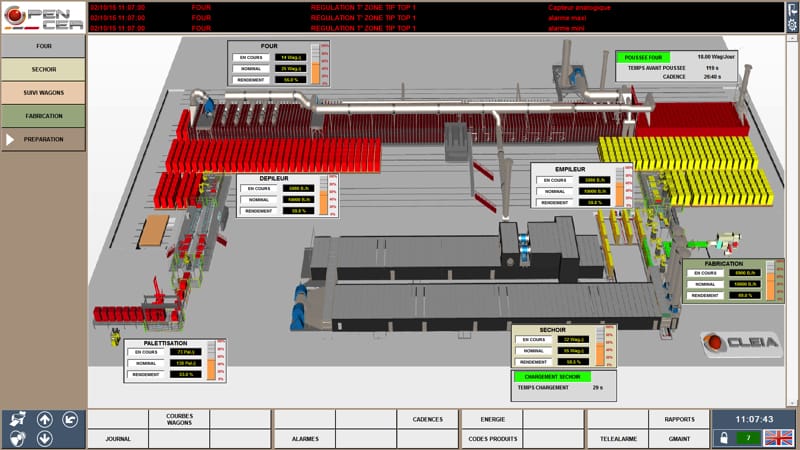

Flow monitoring

Via graphical ergonomical user interface, real-time information allow the flow monitoring.

A specific routing can be programmed according to rules defined by a flow simulation. The management of products / packets stock is configurable thanks to recognition of data such as product, production date, dimensions,…

These data can be transmitted, inter alia to labelling solutions.

Control modules

Combined with the project management, our high-performance control modules allow the automatic management of pre-set firing/ drying/ setting values.

Organized in graphic screens, they integrate analysis and reporting tools to establish production reports that can be completely configurable.