Thermal equipment

Whether it is for the building of high temperature thermal chamber or the design of burners using fossil fuels (gas or fuel-oil for example) or biomass fuels, Cleia provides its customers with a know-how that guarantees the best possible thermal results.

Fuel systems

For each type of power source, fossil or not, the distribution and management systems must be tailored and optimized to ensure an optimum result in terms of product quality and control of the energy bill.

Solutions proposed by Cleia are the result of applied research; these solutions are made reliable and therefore guarantee the best possible results with available fuels.

Aeraulic equipment

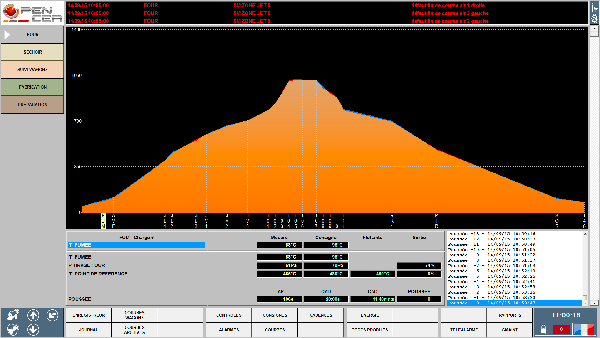

Cleia has developed forced ventilation systems, high-performance aeraulic networks, gaseous flow management systems optimized by aeraulic simulation and continuous computerized process control.

Mastering aeraulic issues allows Cleia to propose solutions for heavy clay and other process industries.

Control and regulation

Always attentive to technological advances, Cleia has developed systems of continuous monitoring and regulation of thermal systems. By managing thermal and mass flows, by driving thermal and aeraulic equipment accurately and carefully, supervisory and regulation software developed by Cleia are genuine control and decision-making tools for the operator.